Bamboo Fishing Rods

Enjoy the sport of fishing as it was originally created with the beauty and prowess of a handmade, authentic 1940’s split-cane, six-sided Bamboo rod.

These rods are built to the original specifications for weight, length, and strength of the prestigious Tuna Angling Club standards.

The six guides and tiptop are highly polished Stainless Steel. Portuguese cork for the foregrip adds lightness and natural feel of the bamboo. A hand turned wooden Ash butt builds added strength and its chrome plated Lakeland reel seats and gimbals depict the era of their time.

A prized possession for any angler.

Reach out or stop by today to place a custom order.

The Bamboo

Split cane rods begin with the selection of Tonkin Bamboo from the Sui River area in southern China.

The cane consists of three layers, a hard outside enamel for the plants natural protection, a middle layer of power fibers for strength, and an inner pithy layer for growth. Some of the outer enamel is removed as is all of the soft inner layer. What remains is the power fibers which are prized for their qualities of lightness, flexibility, and great strength.

Sun-dried strips of only the worthiest cane are handpicked and shipped overseas to the northwest. They are then transported by train to Montana where it is processed by one of the oldest and most world-renowned split cane rod makers - Sweet Grass Rods.

The Production

Strips of these power fibers are cut lengthwise on a bevel then aligned so that the notes or growth rings are spaced apart. The cut tapers are designed to the flex and strength needed, then glued together to dry.

The next step requires that each of these six-sided blanks be hand planed with a Razor blade. Flat filing the outer rough of glue and bark begins the shaping and refining of the rod. He must level off some of the high spots without jeopardizing its structure or strength.

Afterwards four progressive grades of sanding from rough to smooth show the true grain and help to fine tune the flex of the rod.

The tip section of the rod (the bamboo part) is then dipped vertically in a 6 ft length of tube filled with spar marine dark varnish. The rod is drawn up very slowly inside a second 3’ tube above it where it hangs motionlessly drying for a day before it’s placed in a heater box where another two or three days before the varnish hardens. The varnish helps to seal and preserve the bamboo.

Another light wet sanding with 600 grit smooths out any small bumps. Which is followed by another varnish dipping, then drying and a round of wet sanding. Repeating the whole process a third time may also be necessary to reach an optimal level of gloss and smoothness.

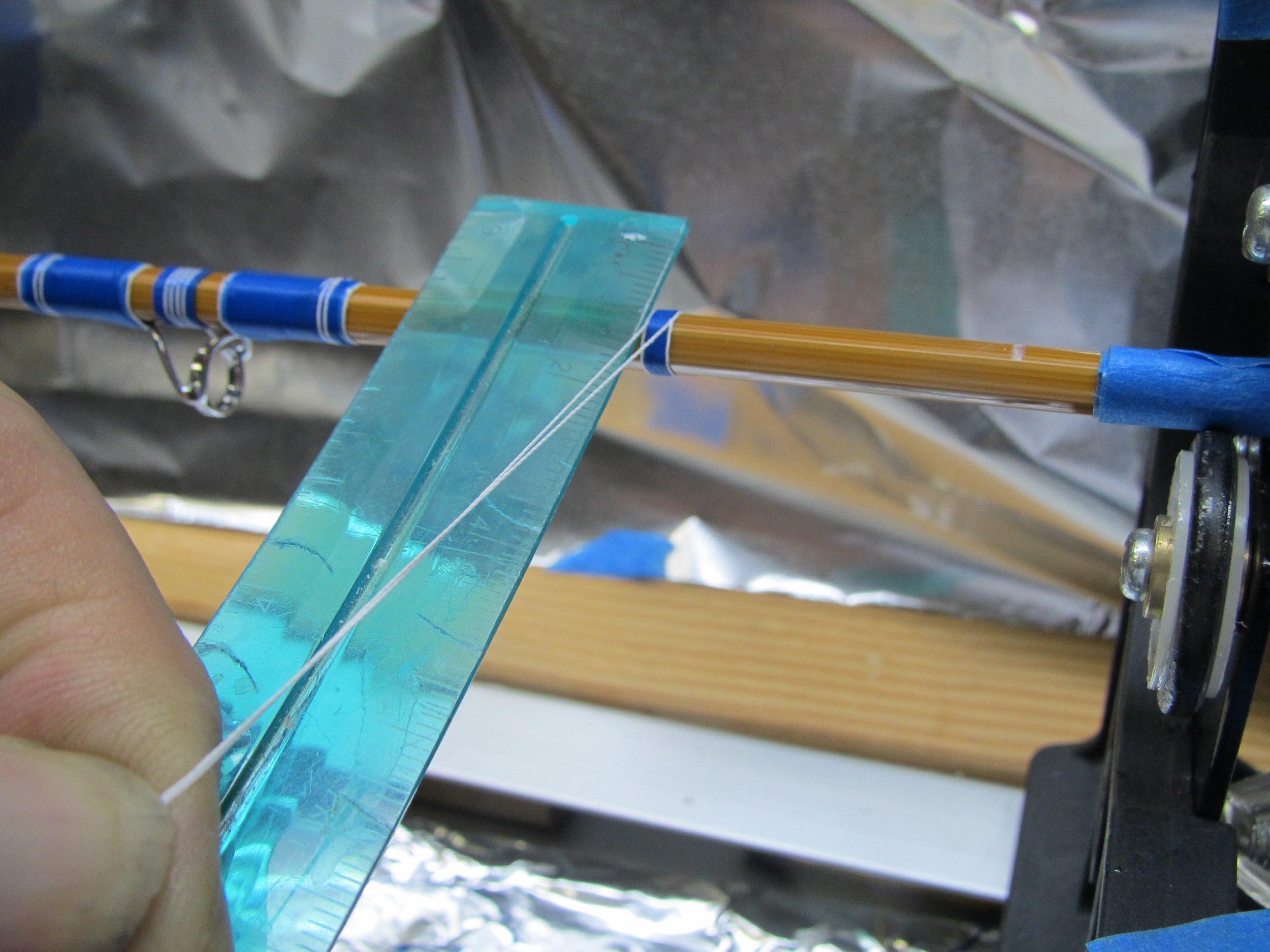

After the rod’s varnish has harden sufficiently, the blank is measured for guide placement. Guides are selected, and the base wraps are put on along with the chromed guides.

The length and weight of the tip of the rod is measured and cut according to the requirements of the Tuna Angling Club rules. Each side will have its own characteristic of natural bend and shape.

The Thread Wraps

The guides are hand wrapped in place using colored thread. Color preserver is applied to the threads and allowed to dry.

A final alignment of guides and double checking of all wraps is made. Next, the first coating of a thinner mixture of epoxy is applied with heat to help liquefy the epoxy and allow it to soak into the thread warps, making it more secure while holding the guides.

Epoxy is allowed to dry for 24 hours in a dust free environment. Upon curing, a check is done for any small thread imperfections, tag ends of threads sticking out, or any finish imperfections. Any such imperfections are cut away with a razor blade or smoothed out.

The guides are taped off for another coating of Epoxy under heat to allow a smooth flowing to top finish the whole thing, and the tape removed for drying.

A small ¼ inch band of thread/trim is now added to strengthen wraps between the guides, then name and serial number unique to each single rod is applied. All followed by a final epoxy coating over the bands and name plate.

Finally, the ash wooded handle is epoxied to the reel seat and the chrome gimbal assembled on the rod.

The rod is now complete.